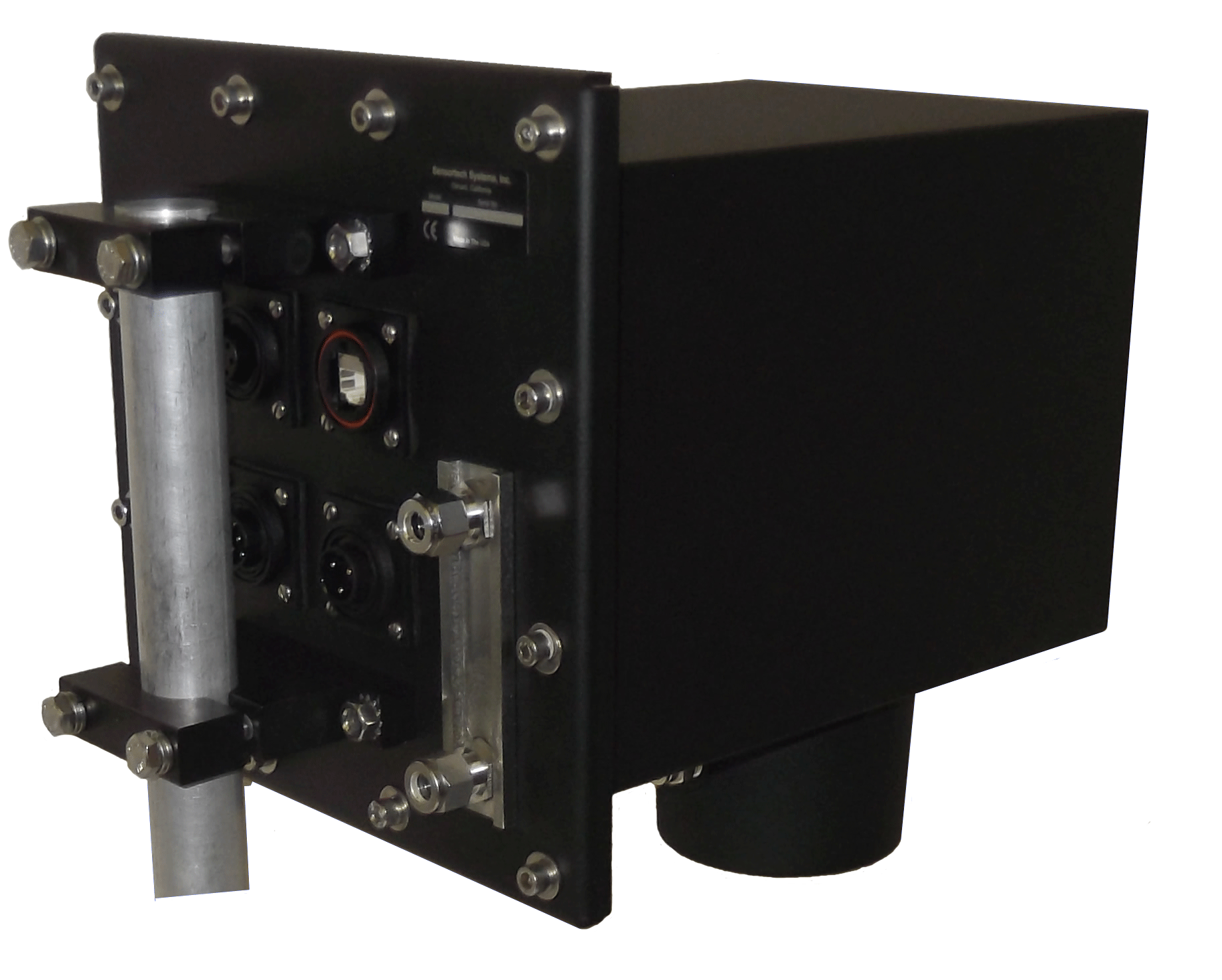

The NIR Series of moisture analyzers are a Moisture Measurement and Control System designed for the continuous monitoring of your product using Near Infrared Reflectance (NIR) technology. Its rugged design provides accurate, real-time, and non-contact measurements in the most demanding manufacturing environments. The NIR Series joins its precision measurement with Sensortech’s Industrial Grade signature.

Sensortech is unique in its ability to deliver dependable performance through its advanced NIR technology, leading edge manufacturing processes, and comprehensive testing and quality control standards. A thorough emphasis on durability had been placed on the NIR Series during its development in order to bring Sensortech’s high standard of performance to industrial applications.

Productspecifications

The NIR 6000 Series of On-Line NIR Moisture Analyzers offer precision measurement and moisture control for industrial applications. Sensortech has pioneered industrial applications of moisture measurement technology for over thirty years and the NIR 6000 Series of moisture analyzers packages the latest NIR technology into a sophisticated instrument engineered for durability and precision measurement. It has been designed to provide accurate readings using the molecular structure of your product and to deliver an effective contribution to your process control.

It’s dynamic technology and easy installation provides significant cost saving and productivity enhancing benefits. The range of communication protocols, intelligent sampling methods, and software utilities of the NIR 6000 Series facilitate the integration of moisture management into your process control system.

Engineered Quality & Durability

Sensortech is unique in its ability to deliver dependable performance through its advanced NIR technology, leading edge manufacturing processes, and comprehensive testing and quality control standards. An emphasis on durability has been placed on the NIR Series during its development in order to bring Sensortech’s high standard of performance to industrial applications.

Process Control

Every analyzer in the NIR Series is equipped with a variety of communication protocols designed to operate in your distributed process control system. Moreover, each analyzer may operate independently with Sensortech’s Digital Panel Meter (DPM), Touch Operator Interface (OI), or third party peripheral devices.

Software Diagnostics

Intuitive Management Software provides an added benefit to the functionality of every analyzer. Our proprietary software package easily installs on your PC and offers an accelerated view of your production process. Among the many features of this powerful software package include: general measurement readings, data-logging, calibration utilities, and analyzer configurations.

Near Infrared Reflectance

Sensortech filters a quartz halogen light source into a series of pulses of specific wavelengths. The filtered beam of wavelengths is directed onto the surface of your product and measures the reflected energy against a reference source. The constituent being measured, typically moisture, is calculated through a specialized amplitude ratio algorithm providing a precision measurement based on your products molecular structure.

MANAGEMENT SOFTWARE

Sensortech’s software diagnostics package offers an expansive range of management resources. These resources provide the ability to configure your analyzer for optimal performance and to thoroughly monitor and analyze your manufacturing process.

Measurement Display

The NIR Management Software supplies an operator with the capability of monitoring up to three measured constituents in addition to a temperature display. A trend plot is displayed for a visual convenience giving the ability to immediately spot production issues and to take corrective action.

Calibration Utilities

The calibration utilities allow you to adjust, fine-tune, or recalibrate your analyzer. It is recommended to consult Sensortech for guidance when employing this powerful feature.

Data-Logging

Data-logging is a useful tool for engineers requiring historical data for statistical analysis. The measurement data is saved to a file that can be viewed by Microsoft Excel or similar programs.

Analyzer Configuration

Many features of the Management Software are dedicated to configuring your analyzer to your requirements. Configurations such as setting the communication protocols, measuring methods, sampling settings, scaling parameters, measurement damping and filtering, and network parameters are among the features available in the Management Software. You have the option to save your configuration settings to a file and reload it at a later date.

Additionally, you may store up to 50 separate product calibrations using any of the available constituents pre-installed on your analyzer.

SPECIFICATIONS:

| NIR Constituents: | 1 |

| Moisture Ranges: | 0 – 100% |

| Measurement Distance: | 4 – 16 in. (10.16 – 40.64 cm.) |

| Optical Sampling Size: | 1.45 in (3.68 cm) |

| Number of Calibrations: | 50 |

| Standard Weight: | 16 lbs. (7 Kg) |

| Enclosure: | Cast Aluminum |

| Power: | 80 / 260 VAC (50 / 60 Hz) |

| Power (Option): | 24 VDC |

| Operating Temperature: | 32 – 131°F (0 – 55°C) |

| Temperature (Options): | Several options are available spanning and exceeding the minimum and maximum stated temperature specifications. |

| Analyzer Inputs / Outputs: | Three self-powered isolated 4 – 20mA outputs Ethernet TCP/IP, RS-232, RS-422/485 1 Digital Input 1 Digital Output |

More information?

Contact us