Applicable standards:

FAK-Merkblatt 201

Zellcheming Merkblatt VI/1/66

Features

• All parts made of non-corrosive materials

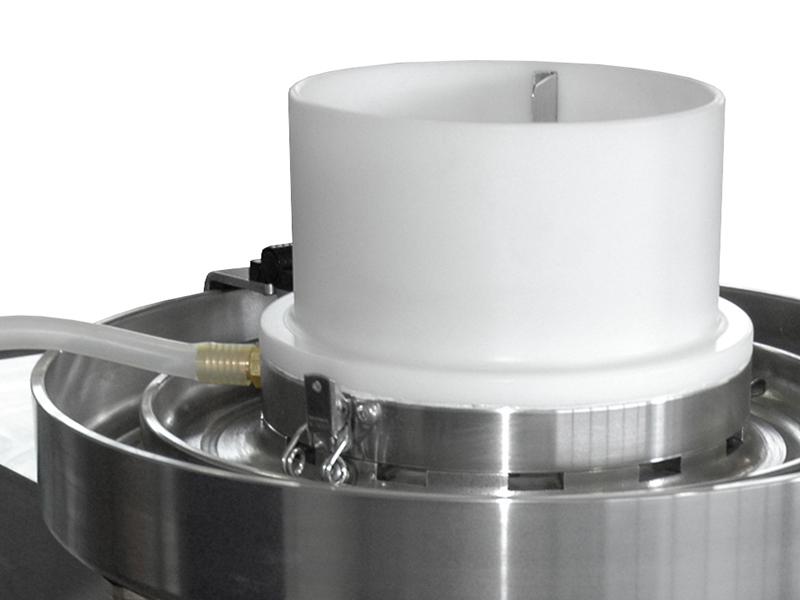

• Standard delivery with slot plate 0.2 mm

Screen # 16: 0.40 mm

Screen # 50: 0.125 mm

• Optional slot plates with 0.15 or 0.1 mm available

• Optional round hole plates with 0.5, 0.7, 0.9 and 1.2 mm available

• Easy adjustment of vertical movement to 6 or 12 mm

Description

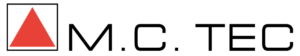

All parts are made of non-corrosive materials. A rubber diaphragm underneath the screen is connected to an eccentric mechanism which in turn is driven by a geared motor. The eccentric runs at 200 rpm and creates a vertical movement of either 6 or 12 mm. The washing chamber above the screen has a ring of jets 7 mm above the screen and the flow is set to either 8 or 10 l/min. Duration of the test 4 -10 minutes. Classification into following classes:

• Shives

• Long fibres

• Short fibres

• Fines

Test description

A sample of 2 g (OD) is prepared (in case of very fine pulp 10 g are used). The correct screen is inserted and the washing chamber closed and locked with both fasteners. The crank is set to the correct vertical movement. The water supply is turned on and flow rate adjusted, then the motor is started (green start button). The sample is shaken to mix, then the timer is started and without delay the sample is poured into the washing chamber taking 30 seconds. After the required time for the test the water supply is stopped and motor turned off. The plug is opened. Remaining fibres are carefully washed from the inner wall of the washing chamber onto the screen. The washing chamber is opened and is checked that there are no fibres left on the rubber seal. All fibres are washed from the screen onto a weighed filter paper. The filter is dried at 105°C until constant weight is reached. The amount in g (o.d.) are weighed and calculated. Further calculations according to Zellcheming Merkblatt VI/1/66.

Specifications

• Vertical movement 6 or 12 mm

• Eccentric runs at 200 rpm

• Water consumption: 8 – 10 litres per minute

• Duration of test: 4 – 10 minutes

• Sample size: 2 – 10 grams

• This instrument can be mounted on top of the cascade of a PTI Bauer McNett classifier for shive content analysis

• Screens:

– Slot plate 0.2 mm

– Slot plate 0.15 mm

– Slot plate 0.1 mm

– Round hole plate 0.5 mm

– Round hole plate 0.7 mm

– Round hole plate 0.9 mm

– Round hole plate 1.2 mm

– Screen # 50: 0.125 mm

– Screen # 16: 0.40 mm

Haindl:

Electricity: 230 V, 50 Hz

Water supply: 2 bar min (drinking water), Drain: ¾” hose

Compressed air: no

Dimensions(WxDxH): 60x50x45 cm

Net weight: 35 kg

Gross weight: 50 kg

Brecht-Holl

Electricity: 400 V, 50 Hz

Water supply: 2 bar min (drinking water), Drain: ¾” hose

Compressed air: no

Dimensions(WxDxH): 45x65x55 cm

Net weight: 40 kg

Gross weight: 60 kg